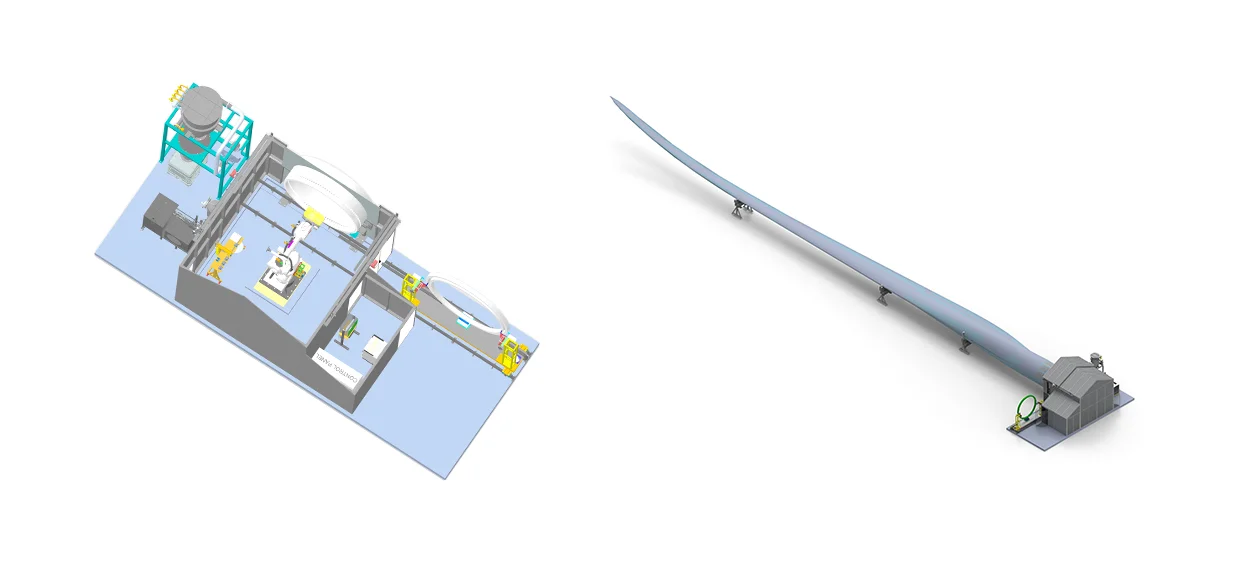

Robotic Root-End Machining for Wind Turbine Blades

First of its kind, machining automation solution for accurate and rapid sawing, milling, and drilling at the root end of wind turbine blades.

Industry:

- Wind Energy

Footprint:

- Customized

Grow Your Business

Bring the power of industrial automation to your wind energy business.

Equipment Videos

Models:

- TurboMac 3000

- TurboMac 4800

Capacity (max Pitch Circle Diameter or PCD)

- TurboMac 3000 - 2800 to 3000 mm PCD

- TurboMac 4800 - 3000 to 4800 mm PCD

Process Flow

We develop efficient

Turnkey

Solutions

for your wind energy business

& Referencing Sawing Ring Removal Drill Location

Marking Drill Location

Manual Verification Axial Drilling Radial Drilling

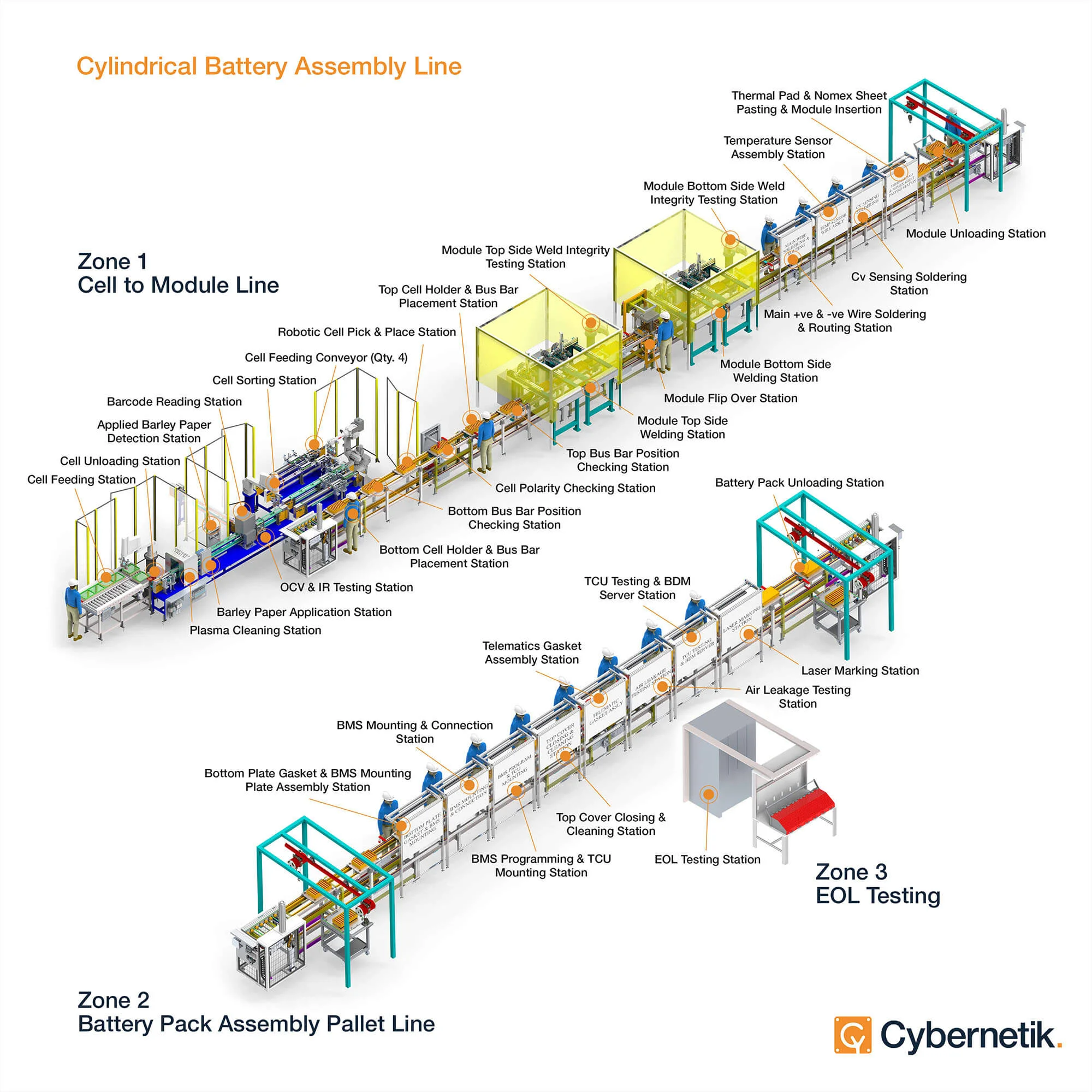

Technical Specifications

| Parameter | Value |

|---|---|

| Throughput | 1 blade / 8 to 10 hr (approx.) |

| Blade Diameter | |

| • TurboMac 3000 | • 2800 to 3000 mm |

| • TurboMac 4800 | • 3000 to 4800 mm |

| Blade Length | |

| • TurboMac 3000 | • 65 to 70 m |

| • TurboMac 4800 | • Up to 100 m |

| Footprint | 15 x 8 m Customizable |

| Electrical Parameters | 65 kW / 87 hp / 112 A 415 VAC, 50 Hz, 3 phase |

| Compressed Air | 275 cfm @ 6 bar |

| Tolerances Achieved (for TurboMac 3000) | |

| • Milling Flatness | • 0.500 mm on Blade |

| • Radial Hole & Milling Plane Parallelism | • <0.250 mm on Mandrell |

| • Axial Hole & Milling Plane Perpendicularity | • <0.25 mm on Mandrell |

| • Intersection Radial & Axial Hole | • <0.250 mm on Mandrell |

| • Axial Hole PCD | • 3000.000 ± 1 mm on Blade |

The Manufacturing Process:

Overhead crane loads the blade on the support structure. Laser scanner determines the centre of the blade at the root end to identify the sawing plane.

Robot picks up the sawing tool and cuts out the ring of excess material from blade.

Shuttle system automatically shifts the cut ring outside the canopied machining area.

For smooth surface finish.

Robot picks up punching tool and marks location of holes.

Operator manually checks positions of holes.

Robot picks up axial tool and drills axial holes (cylindrical) based on coordinates determined by system.

Robot picks up radial tool and drills radial holes (cylindrical) based on coordinates determined by system.

The Cybernetik Advantage

- Process optimization with maximum productivity via sensory intelligence, data logging, and condition monitoring.

- Flexible adjustment to changes in blade PCD, layout, and robot functionality.

- Minimal downtime and maximum equipment efficiency.

- Reduces cycle time by up to 50% compared to special purpose machinery (SPM).

- Improved surface finish and tool life via machining.

- Slurry drying system eliminates need for effluent treatment plant (ETP).

- Chilling unit maintains spindle motor temperature.

- Ring removal system for quick disposal of sawn off ring.

- Consistent high accuracy ensures zero/minimal rework.

- Compliance with CE, UL standards.

Automate your Machining System for Wind Turbine Blades

About Us

Headquartered in India with two design offices and four manufacturing plants, Cybernetik provides automation and robotics solutions to industries across the world.

We tackle complex industrial challenges for leading international brands, by providing expert solutions employing innovative approaches and use of advanced technologies.

HQ - India

Cybernetik Technologies Pvt. Ltd.Gate No. 365, Urawade, Mutha Road, Opp. Indo-German Technology Park, Pune - 412108. Maharashtra, India.

Email: sales@cybernetik.com

0+

Systems Installed Worldwide

0+

Satisfied Customers